Companies offer to buy industrial pumping equipment for technological processes that require low air pressure. Liquid ring vacuum pumps are considered the most popular. They demonstrate high efficiency and can pump various media, including water vapor, gas, steam, and gas.

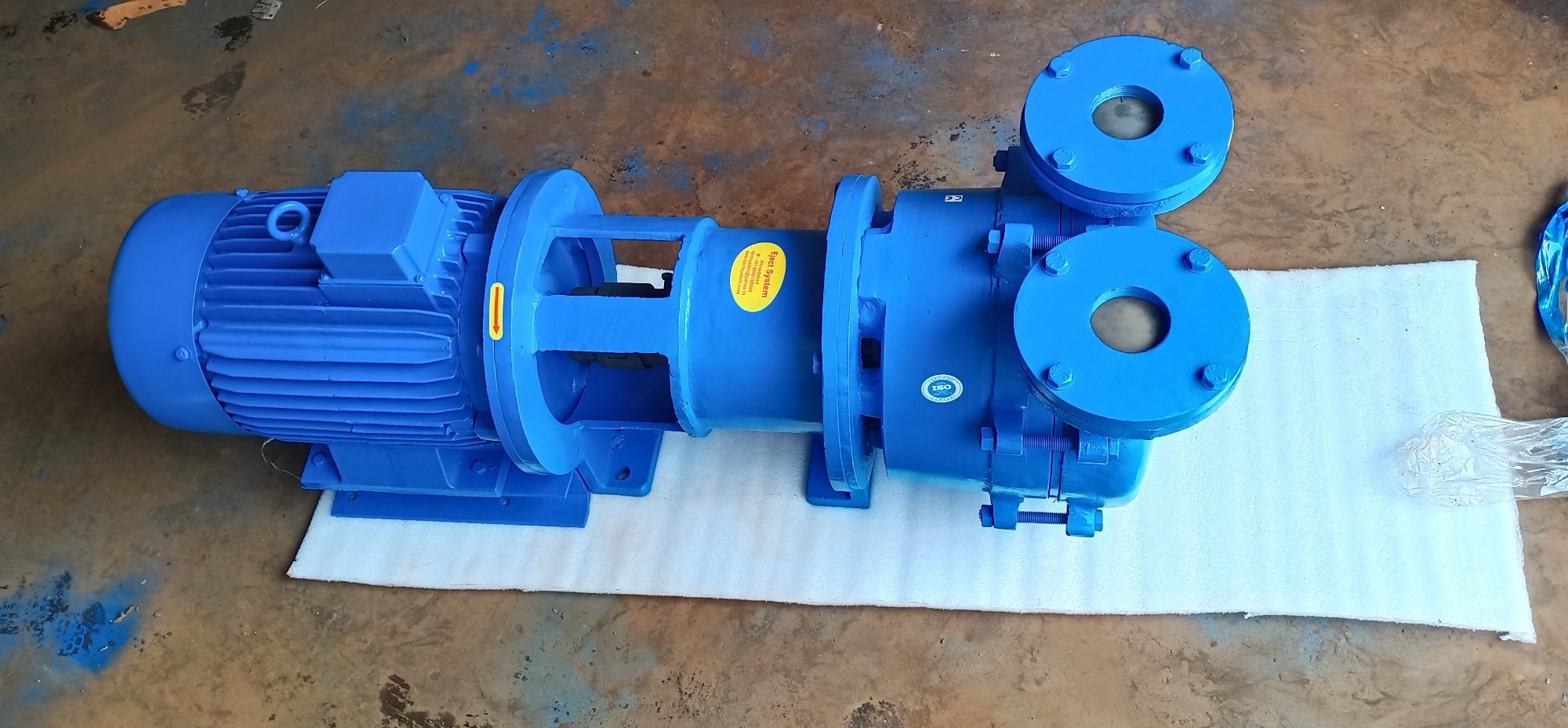

A liquid ring vacuum pump description

A liquid ring vacuum pump differs from other types because its working fluid is water. Other liquid ring vacuum pumps can use an organic mixture, acid, and alkali.

A VVN is designed to create different levels of air rarefaction (depending on the model and modification) up to a deep vacuum. However, this vacuum equipment is not suitable for working with aggressive substances.

Liquid ring vacuum pumps of this category are represented by foreign manufacturers on the market. The cost depends on the model and technical characteristics.

Design features and operating principle

Structurally, a liquid ring vacuum pump is a cylindrical housing with a rotor with radial blades located inside, offset relative to the central axis. The chamber is partially filled with water.

When the rotor rotates, the blades capture the liquid and “throw” it onto the housing walls, forming a water ring. A crescent-shaped cavity with rarefied air is formed in the central part of the chamber, which is divided by the blades into separate cells. As the volume of the cells increases, the pumped medium is sucked in through the inlet. The blades capture gas (or steam) and moves towards the outlet. During the movement, it is compressed due to decreased cavity volume between the rotor and the water ring and is pushed out at the outlet.

Main types

The design of the liquid ring vacuum pump can be made in several versions. Depending on this, there are different compressors:

- single-stage units with a working chamber. The price of such pumps is the most affordable, but their productivity is also lower;

- single-stage with two working volumes;

- two-stage units with two working spaces.

Application area

Liquid ring vacuum pumps can be found in manufacturing and service enterprises and scientific laboratories. The main areas of the industrial sphere where liquid ring compressors are used:

- production of chemical materials and reagents. Distillation processes, crystallization, drying of organic solvents, purification of toxic gas and liquid media;

- wood processing, pulp industry – drying, vacuum filtration, production of cellulose, paper, cardboard;

- metallurgy – production of superconductors, laser crystals, and other products;

- mechanical engineering;

- food industry – malt production, rectification of alcoholic products, water desalination, liquid evaporation;

- manufacture of optical devices – lens enlightenment, surface aluminization;

- pharmaceuticals – purification of raw materials, manufacture and storage of medicines;

- construction – degassing of ceramics;

- production of perfumery and cosmetic products.

Advantages of a liquid ring vacuum pump

The offered liquid ring vacuum pumps have the following advantages:

The wide model range allows you to choose a solution with the required performance and power parameters – specialists can create a unique system that can meet individual needs. In such cases, liquid ring pumps are often used as a basis for multi-stage vacuum systems:

- cost-effectiveness – due to efficient consumption of energy resources;

- high reliability, no failures in operation;

- easy installation, operation, maintenance;

- long service life – due to the absence of elements in contact with each other;