Earthing rods and mats are crucial in electrical safety, protecting against electric shock and static buildup by establishing low-resistance paths to the ground. Proper installation and maintenance are essential to ensure safety for both personnel and equipment in various electrical applications.

Marconite for Earth Resistance

Marconite is a highly conductive aggregate material developed specifically for electrical earthing. Its key benefits in achieving optimal earth resistance include:

- Exceptionally low resistivity (0.001 ohm.m), outperforming traditional materials like bentonite.

- Stability across different soil conditions, including rocky and sandy soils.

- Durability, as it forms a concrete-like structure when mixed with cement, avoiding issues like shrinkage, drying out, or erosion.

- Non-corrosive properties with a neutral pH, making it compatible with steel, copper, and cement structures.

- Long-term reliability, with stable low-resistance values maintained for over 50 years without frequent maintenance.

These properties make Marconite a preferred option for grounding systems in challenging environments, enhancing safety and protecting equipment from voltage fluctuations.

NFPA 780 Ground Rod Standards

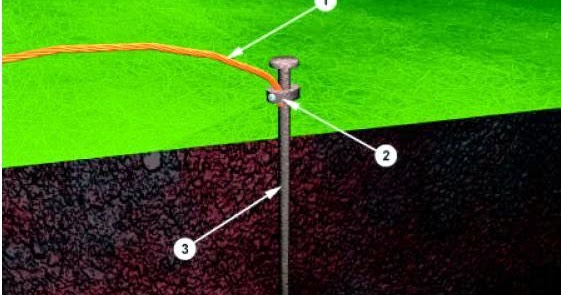

The NFPA 780 standard for lightning protection systems specifies guidelines for ground rod installations:

- Ground rods should be at least 12.7 mm in diameter and 2.4 m long, extending a minimum of 3 m into the ground.

- A minimum spacing of 6 m between rods is required.

- Copper conductors with 2 AWG gauge are recommended for structures under 75 feet tall, and 00 AWG for taller structures.

- Rods should be placed at least 0.6 m from a foundation but not much farther.

- For resistances over 5 ohms, additional rods totaling up to 24.4 m in length may be necessary.

These standards help ensure effective grounding for lightning protection systems, enhancing safety across various structures.

Copper Lattice Earthing Mats

Copper lattice earthing mats are specialized grounding solutions used in high-voltage environments to provide protection against electrical hazards. They are typically made from high-conductivity copper tape in a grid pattern, offering extensive surface area for current dissipation. Key features include:

- Potential grading to reduce step and touch voltages for personnel safety.

- Placement at ground level in high-voltage switchgear locations.

- Available in various sizes and grid configurations.

- Effective in environments where earth rods are difficult to install, typically placed 1m underground.

- Compliance with BS EN 12163 manufacturing standards.

These mats are essential for substation personnel safety and protect sensitive equipment from faults in high-voltage setups.

Ground Rod Material Innovations

Ground rod materials have advanced to improve performance, longevity, and safety across environments:

- Copper-bonded rods: Created by electroplating copper on a steel core, these rods offer excellent conductivity, corrosion resistance, and durability, lasting over 40 years in most soils.

- Knurled copper-bonded rods: Introduced by Galvan Industries, these rods streamline compression grounding installation by eliminating additional tooling.

- Stainless steel rods: Ideal for highly corrosive environments, particularly in areas with high salt or aggressive soils.

- Electrolytic grounding systems: These use hollow rods to draw moisture from the ground, maintaining a constant low-resistance path and dissipating fault currents.

- Marconite: When mixed with soil, Marconite enhances conductivity and requires minimal maintenance for up to 50 years, making it a long-term solution.

- Smart grounding technologies: Innovations include devices and sensors for real-time monitoring, improving reliability and safety in electrical systems.

These advancements in ground rod materials and technology continue to strengthen grounding system effectiveness across various applications.

Comparative Analysis with Bentonite

Marconite and bentonite are both commonly used in earthing systems but differ in several key areas:

- Resistivity: Marconite has far lower resistivity (0.001 ohm.m) than bentonite, which has about 3 ohm.m, making Marconite substantially more conductive.

- Moisture dependence: Bentonite requires moisture for conductivity, while Marconite remains effective in dry conditions.

- Longevity: Marconite systems can last up to 50 years without maintenance, whereas bentonite may need regular water replenishment and has a shorter lifespan.

- Environmental impact: Marconite is chemically inert, while some bentonite compounds may lead to soil pollution.

- Versatility: Marconite performs well in various soils, including rocky, desert, and saline environments, unlike bentonite.

- Structural properties: When mixed with cement, Marconite forms a conductive concrete that adds structural benefits, which bentonite does not offer.

- Cost-effectiveness: Though initially more expensive, Marconite’s durability and low maintenance make it cost-effective over time.

While both materials are useful, Marconite offers superior performance in challenging conditions and for long-term installations.

Mat vs. Rod Selection

Choosing between an earthing mat and an earthing rod depends on application needs, site conditions, and electrical requirements:

Earthing Mats

- Suitable for high-resistivity or rocky soils where rods are hard to install.

- Effective in limited-space environments and high-voltage setups, such as substations.

- Provide a larger surface area for current dissipation and are placed at ground level.

- Ideal when deep drilling is not feasible.

Earthing Rods

- Preferred in conductive soils with adequate depth.

- Cost-effective for residential or small commercial setups.

- Suitable for outdoor installations and temporary grounding needs.

Considerations for Selection

- Soil conditions: Mats work better in poor soils, rods in conductive soils.

- Space availability: Mats suit limited horizontal space, while rods need depth.

- Electrical needs: Mats offer lower resistance for high-current applications, rods suffice for lower currents.

- Ease of installation: Rods are simpler to install but may require multiple placements for desired resistance.

- Maintenance: Mats generally require less upkeep.

For optimal grounding, a combination of mats and rods may be used in complex conditions. In indoor setups where direct earth contact is not possible, grounding mats connected to the building’s electrical ground can provide personal grounding, especially useful in offices and homes.

Summary

Earthing safety is essential for protecting both people and equipment from electrical hazards. Marconite, copper lattice mats, and innovations in ground rod materials offer enhanced conductivity, longevity, and adaptability across different environments. NFPA 780 standards provide grounding guidelines that ensure effective lightning protection, and comparing earthing mats with rods highlights the importance of matching solutions to site and electrical needs. With these advancements and materials, modern grounding systems achieve greater reliability, safety, and efficiency.