In the world of construction and home improvement, rendering has become an increasingly popular choice for enhancing the appearance and durability of buildings. Two key players in this field are concrete rendering and insulation render. In this comprehensive article, we will explore the differences between these two rendering techniques and discuss the latest innovations in the market.

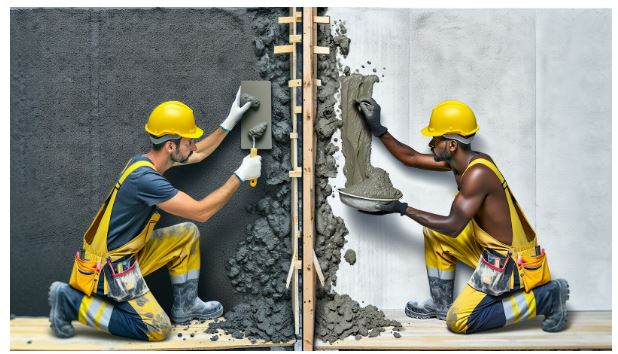

Understanding Concrete Rendering

Concrete rendering is a traditional method of applying a mixture of cement, sand, and water to the exterior walls of a building. This process creates a smooth, durable, and weather-resistant surface that can be painted or left in its natural state.

Benefits of Concrete Rendering

- Durability: Concrete rendering provides a strong and long-lasting surface that can withstand the elements and protect the underlying structure.

- Versatility: Concrete render can be applied to various substrates, including brick, block, and concrete, making it suitable for a wide range of buildings.

- Aesthetic Appeal: With the ability to create a smooth, seamless finish, concrete rendering can significantly enhance the visual appeal of a building.

Limitations of Concrete Rendering

- Lack of Insulation: Traditional concrete rendering does not provide significant insulation properties, which can lead to heat loss and increased energy costs.

- Cracking and Shrinkage: Concrete render is prone to cracking and shrinkage, especially if not applied correctly or if the building experiences significant movement.

- Maintenance: Regular maintenance, such as painting and repairs, may be required to keep the rendered surface in good condition.

The Rise of Insulation Render

Insulation render, also known as external wall insulation (EWI), has gained popularity in recent years due to its ability to combine the benefits of rendering with improved thermal insulation properties.

How Insulation Render Works

Insulation render systems typically consist of an insulation layer, such as expanded polystyrene (EPS) or mineral wool, which is fixed to the external walls of a building. A reinforced base coat is then applied, followed by a decorative finish coat, creating a seamless and energy-efficient exterior.

Advantages of Insulation Render

- Improved Energy Efficiency: Insulation render helps to reduce heat loss through the walls, leading to lower energy bills and a more comfortable indoor environment.

- Reduced Condensation and Damp: By keeping the walls warm and preventing moisture penetration, insulation render can help to alleviate issues related to condensation and damp.

- Enhanced Appearance: Insulation render offers a wide range of decorative finishes, allowing homeowners to customize the look of their property.

- Increased Property Value: The improved energy efficiency and aesthetic appeal of insulation render can contribute to an increase in property value.

Considerations for Insulation Render

- Cost: Insulation render systems can be more expensive than traditional concrete rendering, although the long-term energy savings can offset the initial investment.

- Installation: Proper installation by trained professionals is crucial to ensure the effectiveness and longevity of the insulation render system.

- Planning Permission: In some cases, planning permission may be required before installing insulation render, particularly if the building is listed or located in a conservation area.

Advancements in Concrete Rendering

While insulation render has gained attention for its thermal properties, the concrete rendering industry has also seen significant developments in recent years.

Self-Cleaning Renders

Self-cleaning renders incorporate photocatalytic technology, which uses sunlight to break down organic matter and pollutants on the surface. This helps to maintain a cleaner appearance and reduce the need for manual cleaning.

Breathable Renders

Breathable renders, such as lime-based renders, allow moisture to escape from the walls, preventing the buildup of damp and promoting a healthier indoor environment. These renders are particularly suitable for older buildings with solid walls.

Colored Renders

Advances in pigment technology have led to the development of colored renders that offer a wide range of vibrant and long-lasting colors. This eliminates the need for painting and provides a low-maintenance finish.

Innovations in Insulation Render

The insulation render market has also witnessed significant advancements, focusing on improving performance and sustainability.

Aerogel Insulation

Aerogel, a highly efficient insulation material, has been incorporated into some insulation render systems. Its exceptional thermal properties allow for thinner application layers, reducing the overall thickness of the render system.

Recycled Materials

Some insulation render systems now use recycled materials, such as glass or rubber, as part of the insulation layer. This contributes to the sustainability of the product and helps to reduce waste in the construction industry.

Nanotechnology

Nanotechnology has been employed in the development of high-performance insulation renders. By incorporating nanoparticles, these renders can achieve enhanced thermal insulation, self-cleaning properties, and improved durability.

Choosing the Right Rendering System

When deciding between concrete rendering and insulation render, several factors should be considered:

- Building Type: The age, construction method, and location of the building can influence the choice of rendering system.

- Energy Efficiency Goals: If improving thermal performance is a priority, insulation render may be the preferred option.

- Budget: The cost of the rendering system, including materials and installation, should be weighed against the potential long-term benefits.

- Aesthetic Preferences: The desired appearance of the building, including color, texture, and finish, can guide the selection of the rendering system.

It is essential to consult with professionals, such as architects, builders, and rendering specialists, to determine the most suitable rendering solution for a specific project.

The Future of Rendering

As the construction industry continues to evolve, we can expect further advancements in both concrete rendering and insulation render technologies. Some potential developments include:

- Smart Renders: Renders incorporating sensors and intelligent materials that adapt to changing environmental conditions.

- Biomimetic Surfaces: Renders mimicking the properties of natural surfaces, such as self-cleaning lotus leaves or moisture-regulating cactus skins.

- Carbon-Negative Materials: The use of carbon-negative materials, such as hemp or straw, in rendering systems to reduce the carbon footprint of buildings.

Conclusion

Concrete rendering and insulation render offer distinct benefits and have undergone significant advancements in recent years. While concrete rendering provides durability and versatility, insulation render combines thermal performance with aesthetic appeal. The choice between the two depends on various factors, including building type, energy efficiency goals, budget, and aesthetic preferences.

As innovations continue to shape the rendering industry, it is crucial for homeowners, builders, and architects to stay informed about the latest developments. By understanding the advantages and limitations of each rendering system, and considering the specific needs of a project, stakeholders can make informed decisions that optimise the performance, appearance, and sustainability of their buildings.