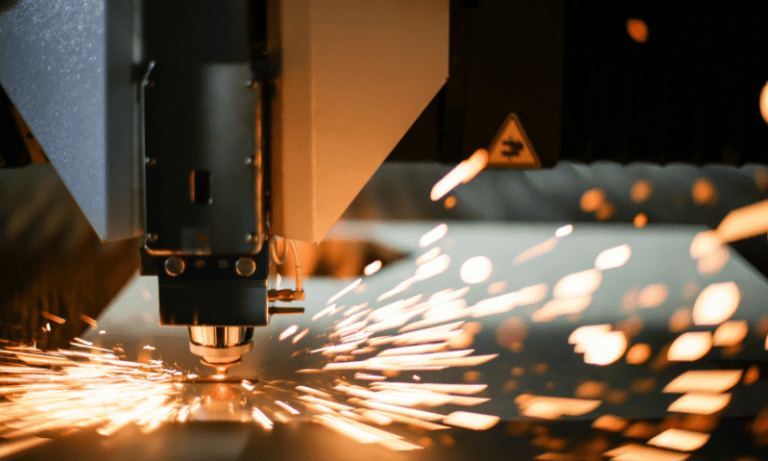

Superior Accuracy with Cutting Metal

Laser cutting is known to be one of the most precise tools and this is one of the biggest merits of the method. With the laser beam precise designs can be made on the material, due to fewer chances of chance of errors or reduced blurring. Such accuracy is of prime importance in markets like aerospace and automotive where a micron difference makes a large difference. Laser also helps create components with sharp features that other techniques are unable to deliver. When hiring cutting services, one is assured of cutting services that make items of a specific quality and standard, and with great performance every time.

Unmatched Speed and Efficiency

Laser cutting is faster than other methods of cutting, and offers an overall productive rate. In high-speed operations and low set-up time, manufacturers can deliver projects faster and still produce quality products. This efficiency also leads to short lead time, thus making it easier for businesses to meet organizational deadlines and execute large volumes of work. Laser cut is also very fast whether it is in prototype production or mass production hence is the go-to tool for modern manufacturing.

Versatility Across Materials

LCA is diverse because it can cut several materials such as metals, plastics, wood, and textiles. Because of its versatility, it can be used in almost any industry including construction, electronics, and much more. From the cutting of stainless steel for the generation of machinery to a decorative material such as acrylic, laser cutting gives accurate cuts. By outsourcing the laser-carved services manufacturers can streamline their operations meaning that one method serves multiple purposes in production.

Cost-effective and Environmentally Friendly

Laser cutting reduces wastage of material since most of the work is done by the laser hence making it cheaper for manufacturers. The accuracy of the work is such that it eliminates wastage of material by having to order more than is necessary for a project. In the same respect, the technology is ecological since it uses less power and has fewer emissions and by-products compared to conventional approaches. laser-carved is advantageous to businesses since they can gain immunity from wear and tear difficulties in the long run to achieve sustainable practices.

Why Businesses Rely on Laser Services

Laser cutting is one of the most important resources that current businesses use to enhance efficiency and performance, due to its precision, velocity, and adaptability. Business enterprises spanning from the small scale to those in the large scale industries are employing laser for them to compete effectively in business. With the help of the enterprises with whom the companies are cooperating by receiving services of cutting, the businesses will be able to improve their performance, increase the quality of production, and satisfy the needs of the constantly evolving market. With National Industries Laser is more than just a tool; it’s a transformative force in modern manufacturing.