In today’s highly competitive manufacturing landscape, efficiency, consistency, and scalability are no longer optional—they are essential for survival and growth. As industries face increasing pressure from rising labor costs, stricter quality standards, and growing customer expectations, packaging machines have emerged as a strategic investment rather than a simple operational tool. Modern packaging machinery plays a crucial role in streamlining production processes, improving product quality, and supporting long-term business objectives across a wide range of industries.

The Growing Importance of Packaging in Manufacturing

Packaging is often the final step in the production process, yet it has a significant impact on product safety, brand perception, and supply chain efficiency. Poor or inconsistent packaging can lead to damaged goods, regulatory non-compliance, and dissatisfied customers. Packaging machines address these challenges by providing precise, repeatable, and efficient solutions that manual methods cannot consistently achieve.

As manufacturers scale their operations, manual packaging quickly becomes a bottleneck. Automated and semi-automated packaging machines allow businesses to handle higher volumes without compromising accuracy or quality, making them an integral component of modern manufacturing strategies.

Operational Efficiency and Productivity Gains

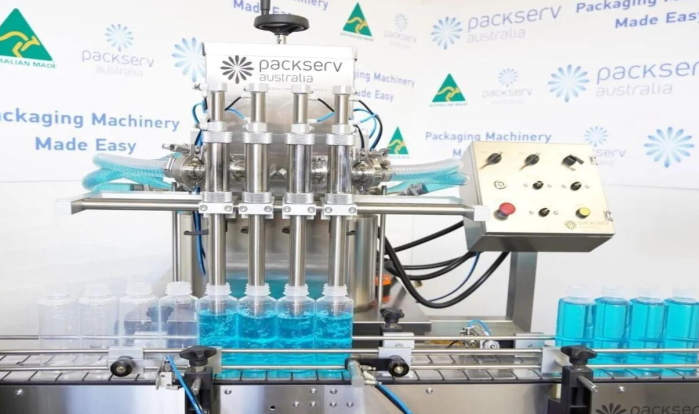

One of the most compelling reasons to invest in packaging machines is the dramatic improvement in operational efficiency. Automated packaging systems can operate continuously at high speeds, significantly reducing cycle times and increasing overall output. Tasks such as filling, sealing, labeling, and palletizing that once required multiple workers can now be completed with minimal human intervention.

This efficiency translates into faster order fulfillment, reduced downtime, and more predictable production schedules. For manufacturers operating in high-demand environments, such as food and beverage, pharmaceuticals, and consumer goods, packaging machines ensure that production keeps pace with market needs.

Cost Optimization and Labor Management

While the initial investment in packaging machinery may seem substantial, the long-term cost benefits are considerable. Automated packaging reduces dependency on manual labor, helping manufacturers manage rising wages and labor shortages. Fewer errors, reduced product waste, and lower rework costs further enhance cost efficiency.

Packaging machines also help stabilize operating expenses. Unlike manual labor, machines deliver consistent performance without fatigue, absenteeism, or variability. Over time, this reliability leads to improved cost forecasting and stronger financial control, making packaging machinery a sound strategic investment.

Enhanced Product Quality and Consistency

Consistency is a hallmark of successful manufacturing operations. Packaging machines ensure uniform filling weights, secure seals, accurate labeling, and consistent presentation across every unit produced. This level of precision is particularly critical in regulated industries such as pharmaceuticals, chemicals, and food processing, where even minor deviations can result in compliance issues or recalls.

By minimizing human error, packaging machines protect brand integrity and help maintain customer trust. Consistent packaging not only meets regulatory requirements but also enhances the visual appeal of products, reinforcing brand identity in competitive markets.

Scalability and Business Growth

As businesses grow, their production needs evolve. Packaging machines provide the scalability required to support expansion without major operational disruptions. Many modern systems are modular and configurable, allowing manufacturers to increase capacity, add new packaging formats, or integrate additional automation as demand rises.

This flexibility enables companies to respond quickly to market changes, seasonal demand fluctuations, and new product launches. Instead of rebuilding processes from scratch, manufacturers can adapt existing packaging machinery to meet future requirements, ensuring long-term operational resilience.

Integration with Modern Manufacturing Technologies

Packaging machines are no longer standalone units; they are increasingly integrated into smart manufacturing ecosystems. Advanced machines can connect with production management systems, sensors, and data analytics platforms to provide real-time performance insights.

Through Industry 4.0 integration, manufacturers can monitor machine efficiency, detect faults early, and optimize maintenance schedules. Predictive maintenance capabilities reduce unplanned downtime and extend equipment lifespan, further enhancing return on investment. Data-driven packaging operations empower manufacturers to make informed decisions and continuously improve performance.

Compliance, Safety, and Sustainability

Modern manufacturing is subject to strict regulatory and safety requirements. Packaging machines are designed to comply with industry standards, incorporating features such as tamper-evident seals, traceability coding, and hygienic designs. Automated systems also improve workplace safety by reducing repetitive manual tasks and minimizing operator exposure to hazardous environments.

Sustainability is another critical consideration. Many packaging machines are optimized to reduce material waste, improve energy efficiency, and support eco-friendly packaging solutions. By enabling precise material usage and compatibility with recyclable or biodegradable packaging, these machines help manufacturers align with environmental goals and consumer expectations.

Competitive Advantage in a Global Market

In a globalized economy, manufacturers must compete on speed, quality, and cost. Packaging machines provide a competitive edge by enabling faster production cycles, consistent quality, and efficient resource utilization. Companies that invest in advanced packaging machinery are better positioned to meet large orders, enter new markets, and maintain high service levels.

Moreover, reliable packaging operations enhance supply chain performance, ensuring products are delivered safely and on time. This reliability strengthens relationships with distributors, retailers, and end customers, contributing to long-term business success.

Conclusion

Packaging machines are far more than mechanical tools—they are strategic assets that support efficiency, quality, scalability, and innovation in modern manufacturing. By reducing costs, improving consistency, enabling automation, and supporting sustainable practices, packaging machinery delivers measurable value across the entire production lifecycle.

For manufacturers seeking to future-proof their operations and remain competitive in an evolving industrial landscape, investing in the right packaging machines is not just a tactical decision but a strategic one. As technology continues to advance, packaging machinery will remain a cornerstone of efficient, compliant, and profitable manufacturing operations.