Most people enter custom printing with excitement. Ideas are clear, designs look great on screen, and expectations are high. But after a few attempts, reality hits. Prints don’t last. Cuts aren’t clean.

Pressing feels unpredictable. This is usually the moment when creators realize that success in customization doesn’t come from creativity alone—it comes from the right tools working together.

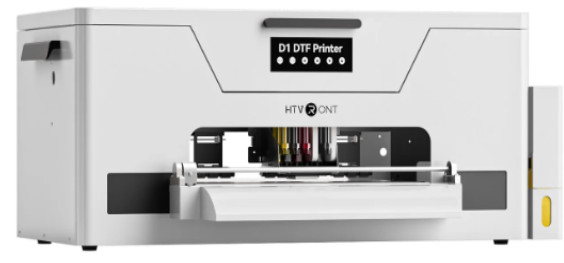

At the core of reliable custom production are three essentials: a dependable dtf printer, a consistent heat press, and a precise vinyl cutter. When these tools are chosen thoughtfully, the entire workflow changes.

Why a DTF Printer Changes What You Can Offer

A dtf printer opens doors that other printing methods simply can’t. It allows full-color designs, fine details, and strong adhesion on a wide range of fabrics. Cotton, blends, dark garments—DTF handles them without the limitations that frustrate many beginners.

But the real value of a dtf printer is consistency. When prints come out vibrant and reliable, creators stop adjusting designs to “make things work” and start focusing on what customers actually want. That confidence directly impacts how many orders you can handle and how professional your output feels.

The Heat Press: Where Everything Is Decided

No matter how good a print looks on film, the final result depends on the heat press. This is the stage where mistakes are either locked in—or avoided completely.

A proper heat press provides:

- Even heat across the entire design

- Controlled pressure for strong bonding

- Predictable timing for repeat results

Without this control, prints may peel, fade, or crack. With it, designs feel smooth, durable, and ready for real-world use. This is why many experienced creators say the heat press is the most important investment in the entire setup.

Why a Vinyl Cutter Still Matters in a DTF Workflow

Some people assume that once they have a dtf printer, a vinyl cutter becomes optional. In practice, the opposite is true. A vinyl cutter adds flexibility and precision to your operation.

With a vinyl cutter, creators can:

- Produce clean text and logos

- Create layered or mixed-material designs

- Offer vinyl-based products alongside DTF prints

- Handle jobs that don’t require full-color printing

This flexibility allows you to say “yes” to more customer requests instead of turning work away.

How These Tools Work Better Together

Each of these tools is powerful on its own—but together, they create a controlled system. The dtf printer handles complex color and detail. The vinyl cutter supports clean, precise design work. The heat press brings everything together with consistent application.

When tools work as a system:

- Production becomes predictable

- Material waste drops

- Turnaround time improves

- Confidence in pricing increases

This is the moment when customization stops feeling experimental and starts feeling professional.

Why Buying Decisions Should Focus on Workflow, Not Price

Many creators make the mistake of buying tools individually based on price rather than compatibility. This often leads to frustration, upgrades, and wasted money later.

When buyers instead think in terms of workflow—how a dtf printer, heat press, and vinyl cutter support each other—the decision becomes clearer. Reliable tools don’t just improve quality; they reduce stress, save time, and support growth.

What Customers Actually Experience

Customers may never ask what equipment you use, but they feel the results immediately. Designs that stay intact. Prints that don’t fade. Cuts that look clean. These details build trust.

And trust is what turns first-time buyers into repeat customers.

From Trying to Producing with Confidence

The biggest shift creators experience after upgrading their setup is mental. Pressing stops feeling risky. Orders stop feeling stressful. Creativity becomes enjoyable again.

That shift doesn’t happen because of talent—it happens because the tools finally support the work instead of fighting it.

Final Takeaway

Custom printing success isn’t about owning more tools—it’s about owning the right ones. A capable dtf printer expands what you can create. A reliable heat press ensures durability and consistency. A precise vinyl cutter adds flexibility and control.

When these three work together, purchasing equipment stops feeling like a gamble—and starts feeling like a smart, confident step forward.